/about/butt_joint-588e41253df78caebc22cb8f.jpg)

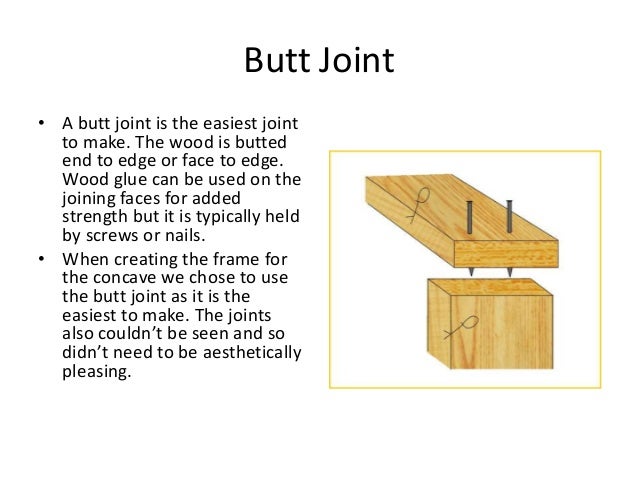

A butt joint is a technique in which two pieces of material are joined by simply placing their ends together without any special shaping. The name ‘butt joint’ comes from the way the material is joint together.

A welding joint is a point or edge where two or more pieces of metal or plastic are joined together. They are formed by welding two or more workpieces (metal or plastic) according to a particular geometry.

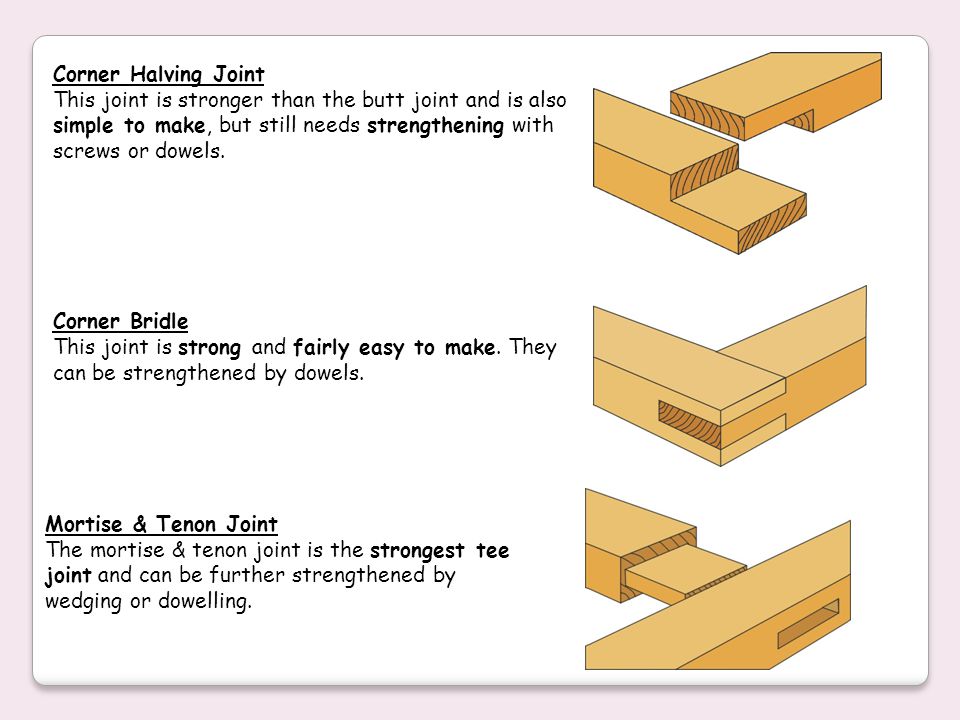

Very little can be accomplished in woodworking without using joints – either to bring pieces together or to make a rigid structure.

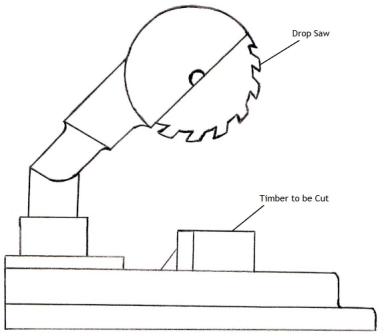

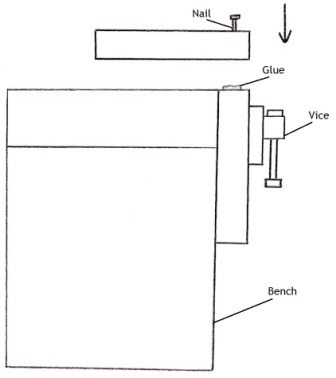

The butt joint is the most basic and simple joint to construct because it is made with only two pieces of timber that are butted together at the ends, this also means that the joint isn’t very strong in fact it is the weakest joint that is used in woodwork but it is also the easiest to make.

butt 1 (bŭt) v. butt·ed, butt·ing, butts v.tr. To hit or push against with the head or horns; ram. v.intr. 1. To hit or push something with the head or horns. 2. To project

Description of joining plywood to make longer sheets to be used in boatbuilding.

/close-up-of-person-working-a-boat-builders-workshop--joining-together-two-pieces-of-wood--761604105-5a6b3320119fa800371affd8.jpg)

I don’t mean any Dancing With the Stars sort of thing. No, to make box joints a fixture jig is used. Hopefully the graphics here will explain all but if not this is how I make mine.

To make a simple square or rectangular frame, cabinet, box or drawer, using butt joints is very easy.

Splines add strength to a miter joint, a simple jig can be made for use on a table saw or router table. Make the back high enough that the picture frame can be clamped to it above your fence.

Choosing a Butt Weld Joint Preparation Which joint configurations provide the best economy? Here is an examination of the “pro-versus-con” arguments that must be weighed out in order to make an informed decision when choosing between U-groove and V-groove joint preparations and small bevel versus large bevel configurations.